|

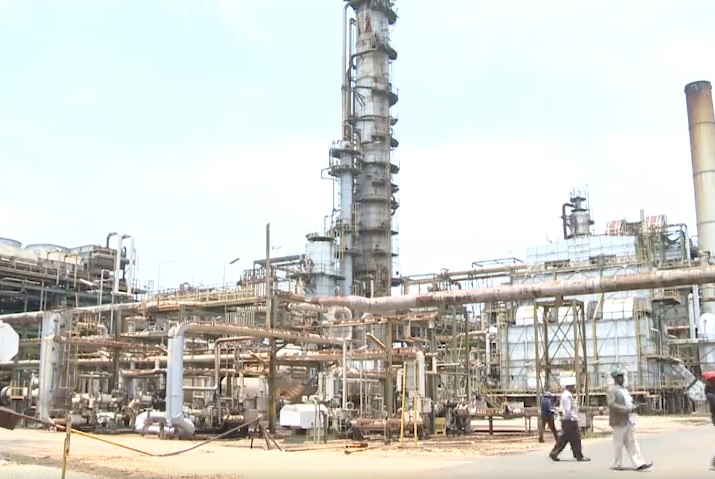

| Kaduna Refinery Image: Supplied |

Bukola Adebayo writes on the effect of

importation of raw materials on Nigerian economy, especially the manufacturing

sector

Kudos to our

indefatigable manufacturers in Anambra State. One cannot help but marvel at the

ingenuity of finished goods that are churned out by designers and traders in

the industrial estate and market in Onitsha, the commercial capital of the

South-East.

Shoes and suits from the

Ariaria market in Aba can be found in closets of top Nigerian celebrities home

and abroad. North or South, local manufacturing of finished goods such as beverages,

clothing items and other consumers products have increased tremendously.

Apart from suits and

shoes, if one checks the labelling on many household goods and

confectioneries in most homes, one would see ‘Made-in-Nigeria’ or a

complimentary local address.

One is also likely to

find the addresses of local companies on many of the drugs used to treat

common ailments like diarrhoea, headache and malaria infections.

However, investigations revealed

that even though many of these products are said to be “Made-in-Nigeria”, they

are actually made abroad.

Manufacturers, who spoke

with our correspondent said due to unfavourable policies, lack of

infrastructure and investment and the moribund state of the petrochemical

and agricultural sector, more than 90% of the raw materials they use are

imported from Italy, Germany, China and other countries.

For instance, the only

raw material that is sourced locally in the production of sachet water,

popularly known as ‘pure water’, is the water itself.

According to the Managing

Director, El-Elyon Water, a producer of sachet water in Ibadan, Oyo State, Mr.

Tola Adeniyi, 80% of the chemicals used in purifying water and the

petrochemicals used in producing the sachet are imported.

Adeniyi said, “When

sachet water manufacturers increased their prices in January from ₦80

to ₦120 per bag, many thought it was informed by fuel scarcity. But the

increment came about because of scarcity of forex.

“You may wonder what

forex has got to do with sachet water. We import every other material used to

purify and package it. None of these chemicals are sourced locally.

“The raw material used to

produce the nylon and print materials are imported; the chlorine and other oxidizing

agents used to purify the water is imported. The prices of these raw materials

have increased by 30% and we can’t shoulder the cost alone.”

It is, indeed,

disheartening that Nigeria, the seventh largest producer of crude oil in the

world, is also one of the largest importers of petrochemicals, a byproduct

of crude oil.

Speaking on the

challenges posed by the lack of raw materials in the packaging industry, the

Marketing Manager, OAK Group of Companies, producers of Lasena water and

plastics, Mr. Eugune Osigwe, warned that the prices of bottled water might

increase, as the cost of importing preforms, the raw materials used to

produce plastic packaging for water and other drinks, has increased.

According to Osigwe, one

tonne of the preform, which is imported from China and was ₦450,000 last

year, is now ₦520,000.

Osigwe said, “The plastic

and paper industry in Nigeria is 90% dependent on importation. Yes, there are

factories producing them, but where are they getting the raw materials? For

instance, the pre-chemical form used to make plastics are got from

petrochemicals, a by-product of crude oil. How many of our refineries are

producing fuel not to talk of the petrochemical used to make plastics? If the

refineries were working optimally, we would have no reason to import plastic

preforms. We would rather be exporting them to other non-oil-producing

countries.”

Apart from exporting

crude oil, Osigwe said, if the refineries were functioning, Nigeria should

be exporting rather than importing leather, alcohol, fertilizers and other

carbon based products .

He said many tyre and

leather manufacturing companies left the country when the hope of getting raw

materials locally dimmed.

“Leather is a crucial

by-product of crude oil. It can be used to make chairs, tyres, shoes, bags and

upholstery just to mention a few. With the crude oil reserves that Nigeria has,

it should be one of the biggest players in tyre and leather industry in the

world, but we are still importing artificial leather from China and Brazil.

“It’s an open secret that

Nigeria imports fertilizers for its farmers, which is a disgrace. Nitrogen and

many chemicals that are used in making fertilizers are by-products of crude

oil. If the refineries were on, we should be exporting, not importing, fertilizers

to agric-based economies like Brazil and the United States. It would have been

be a source of forex which the country direly needs now.

“More than 40% of the

chemicals and raw materials used in paint and print industry can be sourced

from crude, but we are still importing them. Oil has been a curse rather than a

blessing to this country.”

Adeniyi and Osigwe have

every reason to be pained. Nigeria has indeed underutilized the resources that

abound in crude oil.

Apart from PMS, a

report compiled by Ranken Energy, a global manufacturer of petrochemical

products, states that over 5,999 items are made from petroleum by-products.

They include drugs,

cosmetics, detergents, perfume, insecticides, vitamin capsules, floor wax,

paints and dyes to mention a few.

A partial list of

products made from Petroleum (144 of 6000 items)

One 42-gallon barrel of oil creates 19.4 gallons

of gasoline. The rest (over half) is used to make things like:

|

| Source: Ranken Energy |

70 % of

medicines are imported from India, China

Stakeholders were elated

when four pharmaceutical companies in Nigeria got the World Health Organization

pre-qualification to produce some essential drugs for West Africa and beyond.

Experts in the sector proclaimed

that the certification was a guarantee that Nigeria had the capacity to

manufacture and export lifesaving medicines to West African countries and

Africa at large.

But no one was more

surprised when the Chairman, Pharmaceutical Manufacturers Group of

Manufacturers Association of Nigeria, Mr. Okey Akpa, sent a warning to

Nigerians to prepare for scarcity of drugs.

Akpa said that the

lingering shortage of foreign exchange had prevented drug manufacturers from

importing raw materials and chemicals needed to produce essential medicines

into the country.

According to him, many

drug manufacturers have run out of their stock and are unable to replenish due

to dollar insufficiency.

Akpa said, “The only

thing to say at this time is to alert the nation to an impending risk and

threat to drug security in the country. This is going to happen if the current

level of scarcity of forex persists.

“There is going to be

absolute drought of raw materials. This time, we are talking about critical raw

materials, what we classify as active pharmaceutical ingredients. Nearly every

manufacturer is using about the last batch of raw materials and what we

see and foresee is scarcity of medicines – essential medicines. When they are

available, the cost will go up.”

Akpa had every reason to

raise the alarm. Nigeria, with a population of over 170 million people, depends

on India and China for its drug supply.

According to the former

President of the Pharmaceutical Society of Nigeria, Mr. Azubuike

Okwor, over 70% of medicines consumed in the country are imported.

He blamed the moribund

state of the refineries for this situation. Okwor said local pharmaceutical

companies need not import if active ingredients used to produce medicines if

the refineries were working.

He stated, “On local

manufacturing of drug, a greater percentage of the active ingredients for the

local initiatives are all imported, and this is why we call for the creation of

a pharmaceutical commission to drive Nigeria’s journey towards local

manufacturing of pharmaceuticals replicating the giant strides that China and

India have made in these areas.”

Much ado

about tomatoes

If you have had any cause

to buy tomato paste at the market because of the ongoing tomato scarcity, there

is a great possibility that you are consuming a product whose raw material was

sourced in an Asian or European country but packaged in Nigeria.

According to the

Director-General, Raw Materials Research and Development Council (RMRDC), Peter

Onwualu, Nigeria spends over ₦11bn on the importation of 65,809 tonnes of

processed tomatoes annually.

Though Nigeria is ranked

the second largest producer of tomato in Africa and 13th in the world, the

country is also the largest importer of tomato paste, the processed form of the

fruit from China and Italy.

According to the Chief

Executive Officer, Erisco Foods Limited, Ikeja, a local manufacturer of tomato

concentrates, Mr. Eric Umeofia, the Federal Government loses US$1bn to the

importation of tomato products.

Umeofia alleged that 80%

of imported tomato products in the market were sourced abroad, and they

were also adulterated.

He lamented that instead

of exporting packaged products, Nigeria was the destination for adulterated

tomato concentrates from Asian countries such as China.

Umeofia said, “More than

1,000 containers of packaged tomato paste come in through our porous ports and

borders every week. Nigeria is losing US$1bn to tomato paste importation

annually. These importers are mostly foreigners, and they have introduced

fake tomato concentrates into this country. Once you don’t produce and depend

on import, then you give room for fake items.

“Indian businessmen went

to China and asked them to produce tomato paste at a reduced cost. Of course,

the Chinese did so by reducing the content of tomato and filled it up with

starch and added colouring.

“Our research over two

years found out that much of the tomato paste they bring into Nigeria is

poison. In China, they can’t eat the tomato products that are being brought

into this country. So, why are the Indians bringing it here? Because some few

government officials and regulators are aiding and abetting these practices,

Nigerians will be dying?”

Umeofia described the

situation as unfortunate as 70% of tomatoes grown in the country waste due to lack

of storage facilities and infrastructure for processing.

“The tomato farmers in

Sokoto State suffer great losses every year because there is no facility to

store and process them; and the government supports importers rather than

helping local manufacturers.

“We decided to go into

tomato refining and set up a factory with a capacity of 250,000 tonnes to stop

importation but we have been running it at a loss because imported ones

are still coming in. By now, we are supposed to be exporting tomato paste from

Nigeria. We have the capacity and all it takes to achieve it, if government

provides the right policies,” he noted.

Umeofia called on

President Muhammed Buhari not to relent in his administration’s bid to ban the

importation of tomato products, which, he said, would encourage patronage of

local products.

According to him, many

local manufacturing companies have shut down due to unfriendly policies.

He said, “In 2015, we

almost closed down. We couldn’t sell our tomato products because the fake ones

were cheaper to buy. Because the President said no product that could be

made in Nigeria would have foreign exchange allocation, that was when our

business started to pick. Now, we have recalled all the workers we sent away

and we are now employing more. The import law is already having effect.

If Buhari bans the importation of tomato, we will be exporting tomatoes within

18 months.

“If the Federal

Government and regulators give manufacturers 20% of the support they give

foreign investors, we would become one of the biggest exporters of tomato

products in the world.

“Do you know that the

tomato paste industry can create over one million jobs, from the farmers to the

engineers, the processors to the marketers? We need foreign investment, but

it’s only on technology, not on practical goods. The Made-in-Nigeria campaign

can only survive if importation is discouraged entirely,” he added.

The myth

called Made-in-Nigeria food

Before oil boom, Nigeria

was one of the highest producers of grains, vegetables and food crops in

Africa.

It was a taboo to eat

food products that were not grown in the country due to abundance of

agricultural produce.

The reverse is the case

nowadays. According to the Chief Executive Officer, Produce Extracts Limited,

Lagos, makers of locally produced wine, Mr. Linus Kotey, more than 80% of

locally produced soft drinks and beverages sold in Nigeria are made from

imported concentrates.

Kotey, a brewer of over

30 years of experience, spoke to our correspondent when she visited his brewing

company at the Lagos State Small Scale Industrial Estate at Matori. He

warned that manufacturers’ dependence on raw materials from abroad, especially

for food production, could collapse the Nigerian economy.

Kotey said, “Many of the

beverages and soft drinks sold in Nigeria are made from imported concentrates.

Manufacturers find it difficult to go through the chemical process of

converting fresh fruits grown in Nigeria into drinks. I use local pawpaw

and pineapple to make wine, but many brewers won’t do that.

“What the manufacturers

do is to add water and sugar to the imported concentrates, pack them and

millions of Nigerians consume them.

“That does not help the

foreign exchange and the backward integration of local contents. It is sad

because more than half of the fruits produced by farmers in the country go to

waste. Nigeria spends billions importing raw materials it can produce because

there is forex and manufacturers want to take the easy way. The truth is out

now because there is shortage of forex,”

Bread, noodles and wheat

flour products that Nigerians eat daily are said to be “Made-in-Nigeria”,

Kotey, a UK-trained biochemist says this label may be far from the reality.

According to the

industrialist, a significant proportion of the raw materials used in

manufacturing these food products are imported and poor manufacturing policies

from previous governments have allowed the trend to thrive.

Kotey said, “In the

brewery industry at the first regime of Buhari, the government banned the

importation of barley malt used to produce beverages because Nigeria had

sorghum, which is an alternative. The multinationals argued against it but the

government put its foot down.

“I was a brewer and I was

on the government panel, the companies had to implement it. Nigerians were

drinking beer from sorghum and they didn’t know the difference. The policy was

overturned by the government that took over, as local farmers who had

geared up to produce maize and sorghum lost huge sums of money.

“What the foreign companies

do now is that they use 5% sorghum from Nigerian farmers and import barley malt

for the rest and it is still called Made-in-Nigeria.”

Besides poor policies on

the part of government, Kotey said Nigerians had also stopped eating local foods;

they show preference for staple foods whose raw materials, according to him are

sourced abroad.

“There is ongoing food colonization

in Nigeria. I studied in Britain. Britons eat potatoes fried, mashed and baked.

They also grow wheat which they use to make pie or bread. They eat what they

grow. Why are we not eating what we grow? Now everybody is eating noodles,

wheat, semolina, bread and pastries. These are made from wheat that is

imported.

“We are promoting the

agricultural sector of another country. What is wrong with eating fufu, garri,

yam flour, amala and yam in different forms? If Nigeria stops the

importation of wheat today, I can assure you that the agricultural sector will

bounce back.”

Chinese

ankara dominates at Owambe parties

The Nigerian textile

business was one of the most vibrant industries in Africa in the 1960s.Traders

from Ghana, Mali, and Cote d’Ivoire, among others, came to Nigeria to export

the high-quality African print.

Today, the

once-flourishing industry has collapsed such that over 80 of the 100 textile

industries that used to dot the major cities of Kano, Katsina, Lagos and other

parts of the country no longer exist.

According to the Nigerian

Textile Manufacturers Association and the Nigerian Textile Garments and

Tailoring Employers Association (NTMA/NGTEA), China and Korea-made fabrics have

dominated Nigerian market.

The Director-General,

NTMA/NGTEA, Mr. Jaiyeola Olarewaju, stated that the policy by the previous

governments which lifted the ban on the importation of textiles led to the collapse

of over 70 textile companies.

He said that despite the ₦100bn

pumped into the textile industry by the Federal Government, the sector had

failed to recover from the lifting of the ban on importation of fabrics.

“The Chinese textile

manufacturers are squeezing the local industry. The Chinese fabrics have taken

over the market. About 80% of the printed fabrics in the country are imported.

So, it is Asian countries that are enjoying the boom in the use of African

prints, not Nigeria.

“In 1997, we had about

136,000 workers. Now we have less than 20,000. Now that the government has

lifted the ban on importation, what protection is there for local textile

industries?”

Way

forward

Nigeria is one of the

most attractive dumping grounds for exporters due to poor policies and porous

borders. The country still imports furniture, pencils, matches, tooth picks and

other consumer goods that it has the capacity to produce.

According to Kotey and

his colleagues, a majority of the products found in a Nigerian household are

imported.

Stakeholders who spoke to

the Punch correspondent called on the Federal Government to protect local

manufacturers by providing incentives.

According to Kotey, the

only way out is for the Buhari administration to ban the use of imported raw

materials for products that are available locally as it did in the 70s.

He said, “There was a

time that multinationals were using local flavours for their beverages. We

must go back to that. If the government can insist that no manufacturer should

bring in raw materials that can be sourced locally, the economy will thrive.

“Those who want to still import

must be made to pay heavy duties and taxes for this. Gradually, manufacturers

will seek alternatives locally and we can reduce the pressure on the foreign

exchange available.”

Originally published in

The Punch